Basic Working Principle Of An Induction Motor

|

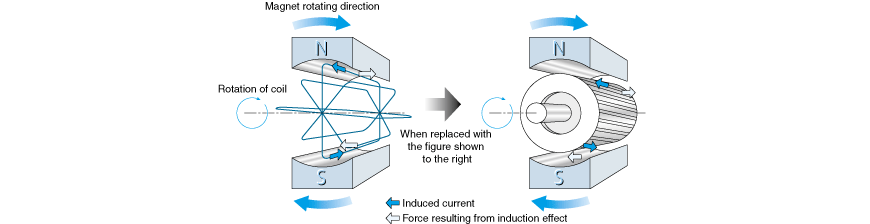

| Add caption |

Induction Motors are the most commonly used motors in many applications. These are also called as Asynchronous Motors, because an induction motor always runs at a speed lower than synchronous speed. Synchronous speed means the speed of the rotating magnetic field in the stator.

There basically 2 types of induction motor depending upon the type of input supply - (i) Single phase induction motor and (ii) Three phase induction motor.

Or they can be divided according to type of rotor - (i) Squirrel cage motor and (ii) Slip ring motor or wound type induction motor

Basic Working Principle Of An Induction Motor

In a DC motor, supply is needed to be given for the stator winding as well as the rotor winding. But in an induction motor only the stator winding is fed with an AC supply.

Alternating flux is produced around the stator winding due to AC supply. This alternating flux revolves with synchronous speed. The revolving flux is called as "Rotating Magnetic Field" (RMF).

The relative speed between stator RMF and rotor conductors causes an induced emf in the rotor conductors, according to the Faraday's law of electromagnetic induction. The rotor conductors are short circuited, and hence rotor current is produced due to induced emf. That is why such motors are called as induction motors.

(This action is same as that occurs in transformers, hence induction motors can be called as rotating transformers.)

Now, induced current in rotor will also produce alternating flux around it. This rotor flux lags behind the stator flux. The direction of induced rotor current, according to Lenz's law, is such that it will tend to oppose the cause of its production.

As the cause of production of rotor current is the relative velocity between rotating stator flux and the rotor, the rotor will try to catch up with the stator RMF. Thus the rotor rotates in the same direction as that of stator flux to minimize the relative velocity. However, the rotor never succeeds in catching up the synchronous speed. This is the basic working principle of induction motor of either type, single phase of 3 phase.

Synchronous Speed:

The rotational speed of the rotating magnetic field is called as synchronous speed.

Snchronous speed Ns=120f/P

where, f = frequency of the spply

P = number of poles

Slip:

Rotor tries to catch up the synchronous speed of the stator field, and hence it rotates. But in practice, rotor never succeeds in catching up. If rotor catches up the stator speed, there wont be any relative speed between the stator flux and the rotor, hence no induced rotor current and no torque production to maintain the rotation. However, this won't stop the motor, the rotor will slow down due to lost of torque, the torque will again be exerted due to relative speed. That is why the rotor rotates at speed which is always less the synchronous speed.

The difference between the synchronous speed (Ns) and actual speed (N) of the rotor is called as slip.

Working principle of three phase Motor

An electrical motor is such an electromechanical device which converts electrical energy into a mechanical energy. In case of three phase AC operation, most widely used motor is Three phase induction motor as this type of motor does not require any starting device or we can say they are self starting induction motor.For better understanding the principle of three phase induction motor, the basic constructional feature of this motor must be known to us. This Motor consists of two major parts:

Stator: Stator of three phase induction motor is made up of numbers of slots to construct a 3 phase winding circuit which is connected to 3 phase AC source. The three phase winding are arranged in such a manner in the slots that they produce a rotatingmagnetic field after 3Ph. AC supply is given to them.

Stator: Stator of three phase induction motor is made up of numbers of slots to construct a 3 phase winding circuit which is connected to 3 phase AC source. The three phase winding are arranged in such a manner in the slots that they produce a rotatingmagnetic field after 3Ph. AC supply is given to them.

Rotor:Rotor of three phase induction motor consists of cylindrical laminated core with parallel slots that can carry conductors. Conductors are heavy copper or aluminum bars which fits in each slots & they are short circuited by the end rings. The slots are not exactly made parallel to the axis of the shaft but are slotted a little skewed because this arrangement reduces magnetic humming noise & can avoid stalling of motor.

The stator of the motor consists of overlapping winding offset by an electrical angle of 120°. When the primary winding or the stator is connected to a 3 phase AC source, it establishes a rotating magnetic field which rotates at the synchronous speed.

Secrets Behind the Rotation: According to Faraday’s law an emf induced in any circuit is due to the rate of change of magnetic fluxlinkage through the circuit. As the rotor winding in an induction motor are either closed through an external resistance or directly shorted by end ring, and cut the stator rotating magnetic field, an emf is induced in the rotor copper bar and due to this emf a currentflows through the rotor conductor. Here the relative speed between the rotating flux and static rotor conductor is the cause of current generation; hence as per Lenz's law the rotor will rotate in the same direction to reduce the cause i.e. the relative velocity.

Thus from the working principle of three phase induction motor it may observed that the rotor speed should not reach the synchronous speed produced by the stator. If the speeds equals, there would be no such relative speed, so no emf induced in the rotor, & no current would be flowing, and therefore no torque would be generated. Consequently the rotor can not reach the synchronous speed. The difference between the stator (synchronous speed) and rotor speeds is called the slip. The rotation of the magnetic field in an induction motor has the advantage that no electrical connections need to be made to the rotor.

Comments

Post a Comment